1. INTRODUCTION

Ration is one of the essential necessities for everyone who lives below the poverty line, and ration cards may be used to prove an address, identify family members, and other things. In a country like India, a large number of individuals struggle to purchase food for their daily necessities. The government of India distributes many goods to the public through its rationing program, which includes wheat, rice, oil, and kerosene etc. Other nations outside India also provide their citizens with the necessities. However, there are several issues with the present system, including fraud and the smuggling of commodities. Because of this, the government's services will not be able to reach all sectors of people. In order to implement our project, we kept in mind the fundamental issues with the present system and the levels where adulteration occurs most frequently. We implemented system that is easy to use and accessible to all villagers’ residents. The Food Corporation of India issues smart ration cards to everyone who is qualified to receive rations. Beneficiary must swipe the smart card via the RFID scanner to view customer-related information, and then the automated dispenser may dispense the ration without human interaction. As a result, our project goal is to ensure that the ration distribution system is free from corruption. So, buyers can now engage with government-authorized employees directly, so there is transparency in the system.

2. PROJECT BUILDING

STEP 1

- Make sure that you have all the components necessary to build the project.

- Needed components are given in the below figure.

STEP 2

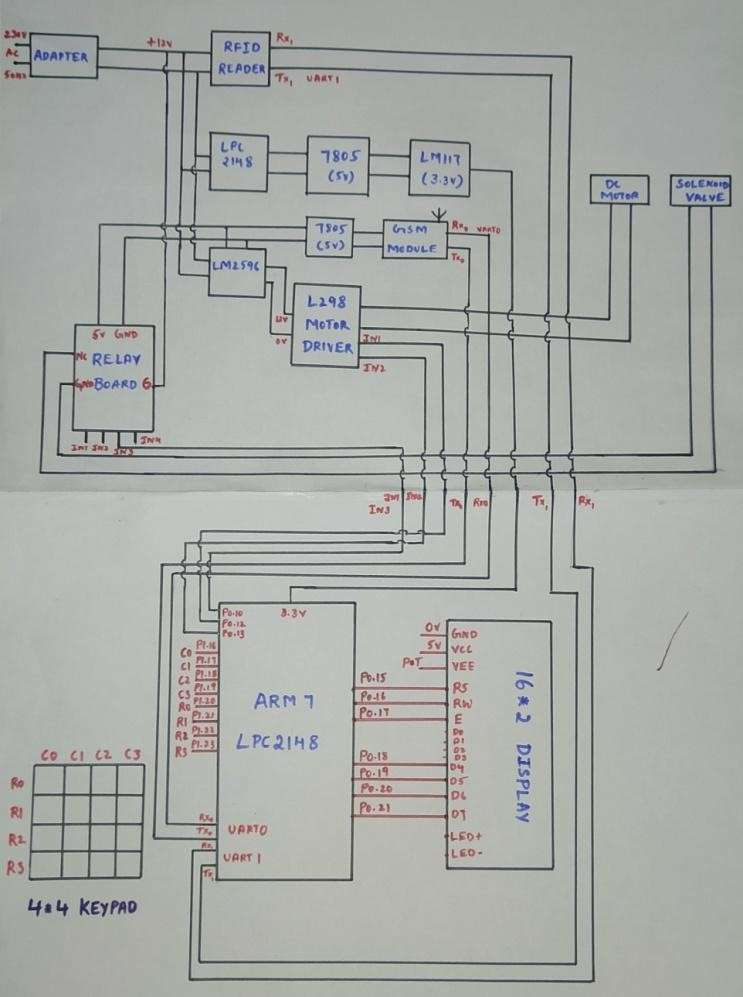

- Make the connection as per the pin diagram.

- The pin diagram & circuit connection is shown below, the code is given in code block section.

.png)

STEP 3

Upload the given code to ARM7 microcontroller using Keil software.

#include <LiquidCrystal.h>

LiquidCrystal lcd(7, 6, 5, 4, 3, 2);

#include <SoftwareSerial.h>

SoftwareSerial mySerial(9, 10);

int gasValue = A0; // smoke / gas sensor connected with analog pin A1 of the arduino / mega.

int data = 0;

void setup()

{

randomSeed(analogRead(0));

mySerial.begin(9600); // Setting the baud rate of GSM Module

Serial.begin(9600); // Setting the baud rate of Serial Monitor (Arduino)

lcd.begin(16,2);

pinMode(gasValue, INPUT);

lcd.print (" Gas Leakage ");

lcd.setCursor(0,1);

lcd.print (" Detector Alarm ");

delay(3000);

lcd.clear();

}

void loop()

{

data = analogRead(gasValue);

Serial.print("Gas Level: ");

Serial.println(data);

lcd.print ("Gas Scan is ON");

lcd.setCursor(0,1);

lcd.print("Gas Level: ");

lcd.print(data);

delay(1000);

if ( data > 500) //

{

SendMessage();

Serial.print("Gas detect alarm");

lcd.clear();

lcd.setCursor(0,0);

lcd.print("Gas Level Exceed");

lcd.setCursor(0,1);

lcd.print("SMS Sent");

delay(1000);

}

else

{

Serial.print("Gas Level Low");

lcd.clear();

lcd.setCursor(0,0);

lcd.print("Gas Level Normal");

delay(1000);

}

lcd.clear();

}

void SendMessage()

{

Serial.println("I am in send");

mySerial.println("AT+CMGF=1"); //Sets the GSM Module in Text Mode

delay(1000); // Delay of 1000 milli seconds or 1 second

mySerial.println("AT+CMGS=\"+91900xxxxxxx\"\r"); // Replace x with mobile number

delay(1000);

mySerial.println("Excess Gas Detected. Open Windows");// The SMS text you want to send

delay(100);

mySerial.println((char)26);// ASCII code of CTRL+Z

delay(1000);

}

STEP 4

- After all the setup, press 1 using keypad to activate the ARM7 microcontroller and GSM.

- A message regarding to collect the ration will be delivered to the particular customer's mobile number.

- The customer needs to scan the RFID tag with RFID reader.

- If the card is valid then his name is displayed in LCD display then simultaneously a 4 digit OTP will be delivered to phone number.

- He had to enter the OTP using keypad then list of ration will be displayed with numbers in lcd display.

- When the number is entered the particular ration will be dispensed to the collector.

3. DEMONSTRATION VIDEO

4. BRIEF DESCRIPTION

DESIGN AND METHODOLOGY OF SRDS

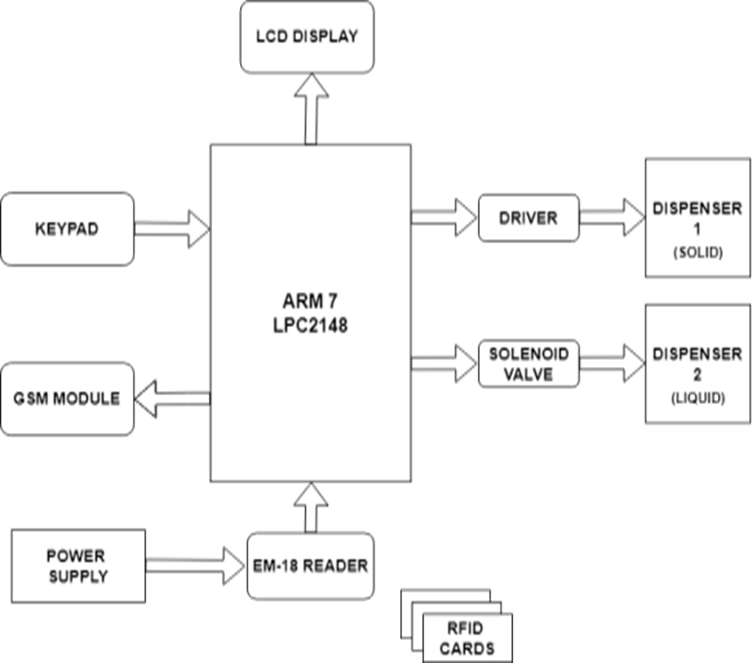

3.1 BLOCK DIAGRAM

The block diagram of the Ration Dispensing System is shown in the fig 3.1. This gives us an overview of the complete project and its components used.

Fig. 3.1: Schematic Representation of RDS.

The transformer which we are using for the purpose of the power supply is connected to the bridge rectifier it is been used to rectify the supply. The entire system is supplied with the external power supply which is turned on using the 12V DC Adapter. The system contains the main module i.e., ARM 7 LPC2148 micro controller which will be the main controller of the project.

The LPC2148 board will control the entire working and also will perform the tasks based on our requirements. This LPC2148 board will help the working of entire logic. Since the system is RFID based which is the main advantage of the system proposed. This RFID is an individual card with a unique identification number distributed to each eligible person for the ration supply. When buyer swipe the smart card to the EM-18 module will transfers information to the controller. If it is wrong card or if ID is not valid then user will be notified stating it is an invalid card, else the process will move further. The OTP (One Time Password) is also verified through the keypad option. The controller will then check if it’s grains or liquid and then turn on the specific driver based on the quantity entered in the Keypad. Based on the keypad details specific driver will be on and the dispenser will be opened so that specific quantity of the ration will be dispatched. The entire system will be controlled and the information will be displayed in the LCD Display that is integrated to the LPC2148 board. This entire process will be looped through from scanning the RFID cards.

Two cases were identified in this system for dispense the ration materials automatically i.e.,

Case 1:

- If ration preferred is liquid, the keypad is activated and will wait until quantity is entered. Then the valve for dispensing the liquid ration will open and the dispenser will dispense the ration.

- The same step repeats from waiting for a new card to be placed on the reader to dispense the next round of the ration.

Case 2:

- The other case, if the ration is grains, the quantity is asked and then proceeded to start the driver to open the gateway to grains distribution and after the required amount of grains is delivered then the system is stopped.

- The same step repeats from waiting for a new card to be placed on the reader to dispense the next round of the ration.

3.2 FLOW CHART

.png)

Fig. 3.2: Flow Chart

WORKING

In this project we are making use of RF ID Card to authenticate the user, once the user shows the card in front of the RFID reader then that data is fetched to the microcontroller.

- Every consumer is provided with a RFID card who are registered in the Food Corporaion of India throug PDS.

- When consumer goes to the Fair Price shop (FPS), he/she has to carry the smart card and mobile phone.

- Now the customer has to scan the RFID card.

- If the RFID card is valid it displays the consumer name in LCD display. If the card is invalid means it display “INVALID CARD”.

- The above step is correct means registered mobile number receives an OTP which can be used as password.

- Now the customer has to enter the 4 digit OTP received the mobile through keypad.

- Based on type of material chosen by the consumer, the motor or solenoid valve is activated.

- After collecting proper quantity material, motor or solenoid is disabled.

IMPLEMENTATION

.png)

Fig. 3.20: Circuit Connection

This proposed system consists of electronic components like ARM7 LPC2148, EM-18 Reader, LM2596 (DC-DC converter), L298 Motor driver, GSM module, DC gear motor, solenoid valve (SV), 16*2 LCD, 4*4 Keypad. We have used waste plastic materials to build containers using 3D printer for automatic dispense of ration materials. Firstly, the circuit connection has to be done as shown in figure.3.20.

.jpeg)

Fig. 3.21: Pin configuration

The system needs power supply which is supplied by using adapter that converts AC supply 230V to 12V for the circuit. This 12V supply is divided for the various components in this circuit. The supply which is an input for the RFID reader i.e., EM-18 reader module then the output of this Tx and Rx pins directly connected to the main controller board for the pin called UART 1. Same 12V supply is given to the ARM7 which converts internally and provides 3.3V. LM256 (DC to DC converter) that converts 12V to 5V and connected to an input for the relay module, motor driver and GSM module. The output of the GSM Rx and Tx is connected to the main board with the pin name UART 0. For automatic dispense of the ration is done with the help of the motor driver which as the input pin IN1, IN2 is directly connected to P0.12, P0.13 ports of ARM7 and the output pin is connected to the DC gear motor. While, the relay module is used to operates the solenoid valve (SV) to control the flow of liquids. In this the input pins IN3 is connected to the port of main controller pin called P0.10 and output is connected to the end of the solenoid valve.

Then, for the display of necessary information we have LCD which is connected to the respective pins D4, D5, D6, D7 with the ports of controller P0.18 to P0.21 and the Read Write (RW), Enable (EN), Register select (RS) pin of LCD is connected to P0.15 to P0.17 of the controller. To enter the OTP or to select the type of ration we have used here is 4*4 keypad which has 16 pins i.e., 4 columns C0, C1, C2, C3 is connected to P1.16 to P1.19 and 4 rows R0, R1, R2, R3 pins are connected to the port of the controller P1.20 to P1.23. The pin configuration of this model is shown in the figure 3.21.

RESULTS AND DISCUSSIONS

Ration Dispensing automation is a growing trend that shows no sign of slowing down. Continued automation technology will drive system/organizations to an ever-greater level of efficiency and performance. In order to stay competitive in your particular market, we have to upgrade the system and educate the people.

4.1 SNAPSHOTS

.jpeg)

Fig. 4.1: Smart Distribution System Setup

The Smart ration distribution system has been implemented and working was shown in fig 4.1. which consists of ARM7, 16x2 LCD display, 4x4 keypad, Relay, GSM module, RFID reader, L298 driver.

.png)

Fig. 4.2: Swiping the Passive RFID Tag

Fig 4.2. shows that at the time of ration collection customer has to swipe the smart card provided by the government with EM-18 reader.

.png)

Fig. 4.3: Displaying the Consumer’s Name

Fig 4.3. Shows that once the smart carrd was swiped successfully 16x2 LCD displays the consumer’s name.

.jpeg)

Fig 4.4: Enrolled Number Get an OTP

Now customers receive an OTP which can be used as password for further process it is show in the above fig 4.4. If the entered password is wrong “Displays Password Invalid”.

.png)

Fig 4.5: Select the Quantity

Fig 4.5. Shows we have to select the quantity of ration through input 4x4 keypad here (button 1 and 2 for liquid item) and (button 3 and 4 for grains).

.png)

Fig. 4.6: Dispensing the Ration Through Automatic Dispenser

Fig. 4.1.27. Once all the above procedure completed successfully the respective dispenser will be activated and automatically dispenses the rations.

ADVANTAGES AND APPLICATIONS

ADVANTAGES

- Easy to use

- Data Integrity

- No mediator Cheating

- Flexibility

- The purpose of project is useful for the society at Panchayat Level for ration distribution.

- The government services are reached to poor people and also the corruption in PDS can be reduced or avoided to a great extent.

- The main advantage here is that the beneficiaries get their rightful entitlement in terms of quantity.

- Less man power required.

- It becomes easy to the needy people to access the ration without any Hassel.

- We can maintain the centralized monitoring system to monitor each and every area about the usage.

APPLICATIONS

- The ration items will be effectively delivered to the valid ration card holders who are below poverty line.

- The main advantage here is that the beneficiaries get their rightful entitlement in terms of quantity. What's meant for them cannot be diverted to the open market because of maintaining the database correctly.

- A common practice adopted by commission agents who run FPS is that they charge people more than the mandated rates, and they often under-weigh the commodities. But using this technique they cannot do so because each and every item will be having its own code and the price will be generated from that code and hence no overcharge can be done.

- The government services are reached to poor people effectively and also the corruption in PDS and FPS can be reduced or avoided to a great extent.

CONCLUSION AND FUTURE WORK

The current classical method has two flaws. Firstly, human error might lead to an incorrect estimate of the goods weight. Secondly, without notifying the customers, the commodities may be sold to others if they are not purchased at the ration shop during the month. The suggested solution can be used to resolve the above limitations. Due to its high accuracy, this device is suitable for actual-time applications. Under the digital India, we may further improve the use of face recognition and biometric identification. Hence, on the basis of a review of literature survey and by looking at the current system. We have determined that the recommended device will help to automate the system. Initially implementation of this project takes time once if it is implemented all the people who are eligible for these facilities will get food supply under the Act of right to equality and Consumer rights and we can able to educate them the new technologies so that they will be updated in future to use the upcoming automated system.

FUTURE WORK

- In future, high-quality sensors and hardware can be used for efficient implementation.

- This Automatic rationing system can be converted in different regional languages.

- In future, Payment can be done online by connecting customers bank account directly to the PDS account due to this human interference in transaction process will be reduced completely.

- GPS tracking of the PDS delivery trucks can also be done. Online quotation can be opened for farmers, connecting them directly with the government authorities.

Apart from being limited to this specific domain, the application of this particular improvement in the current working of the ration shop has a lot of scope in various other areas. This system can be re sized up to handle a large number of items which can be chosen from a single controller. Furthermore, the technology introduced can be used in a variety of places such as malls, supermarkets, and so on. We can also offer a one-time password that functions similarly to an ATM card. If a system is profitable, some companies could choose to implement it.