Introduction:

Peltier effect is the major idea behind this project

PELTIER EFFECT - The Peltier element also known as thermoelectric cooling is an electrothermal transducer. Here, based on the Peltier effect, a temperature difference is generated when current flows through it or a current flow is generated when there is a temperature difference. Therefore, it can be used for both cooling and heating.

First step:

(Check working of Peltier) Checking the working of the Peltier module, just by keeping the hand on one side of it... the number written on it is the cooler side and the other is the hotter side .. kept hands on hot side and a small rise in voltage in millivolts.

Second step:

(Analysis of temperature vs voltage output of Peltier)Then tested the Peltier by heating and we measured the voltage output for every stage . When temperature rises the voltage will rise ..as said in the peltier effect the temperature difference will create a voltage. The peltier can withstand upto 100 degree centigrade.

Third step:

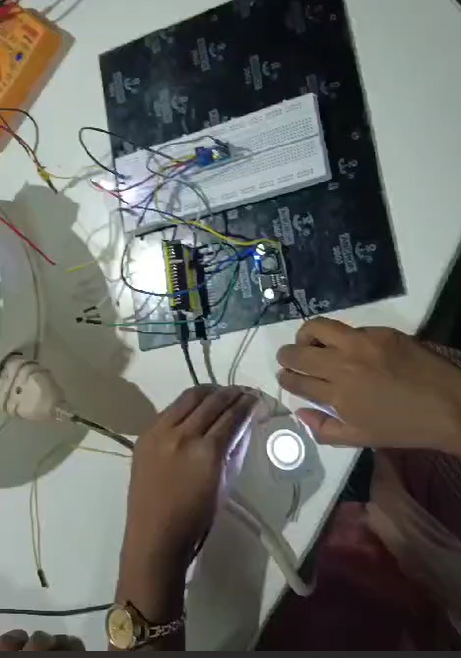

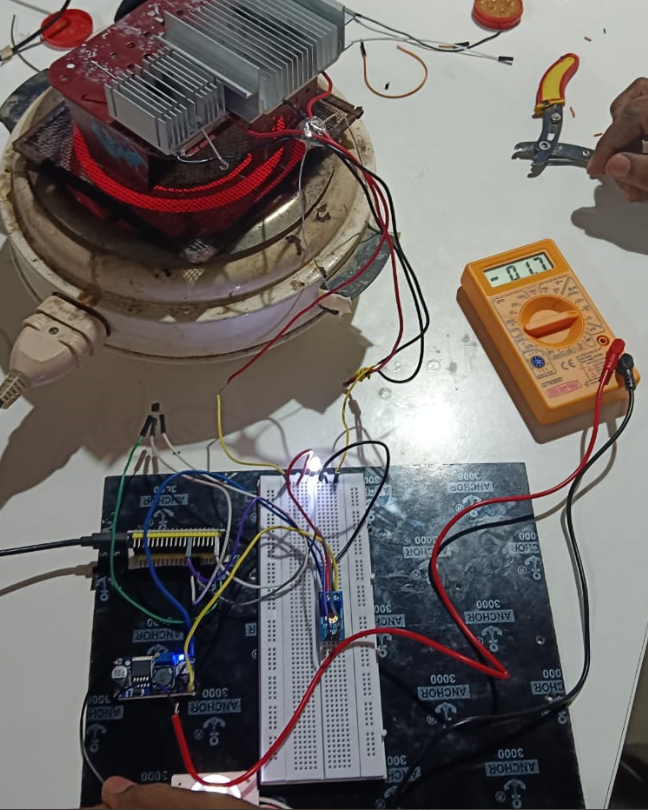

(Sensor implementation and code implementation using esp32)After measuring a significant output of nearly 2 volts from a single Peltier , we combined 2 Peltier in series.. the another major component is heat sink... without heatsink the Peltier cant produce this much of output. Peltier is attached in the cooler side of the peltier using heat sink paste to keep the cooler side at low temperature(note: we say one of the side as cooler, but when we heat continuously both sides will become hot only....we have keep the cooler side as cooler as possible) . When we combined two peltiers we got a reasonable output of about 3 volts.

Fourth step:

(booster implementation)We have provided the output of nearly 3 -3.2 volts to the boost converter module. Boost convertor can increase the the input of 3v to 12v (studies from datasheet) , as a evidence of it we lighted up 12v led. We noticed a output of above 15 v from booster

We used voltage and temperature sensors connected with ESP32 for sensing the voltage and temperature from the Peltier and we showed the output in webhost .This is IOT based.

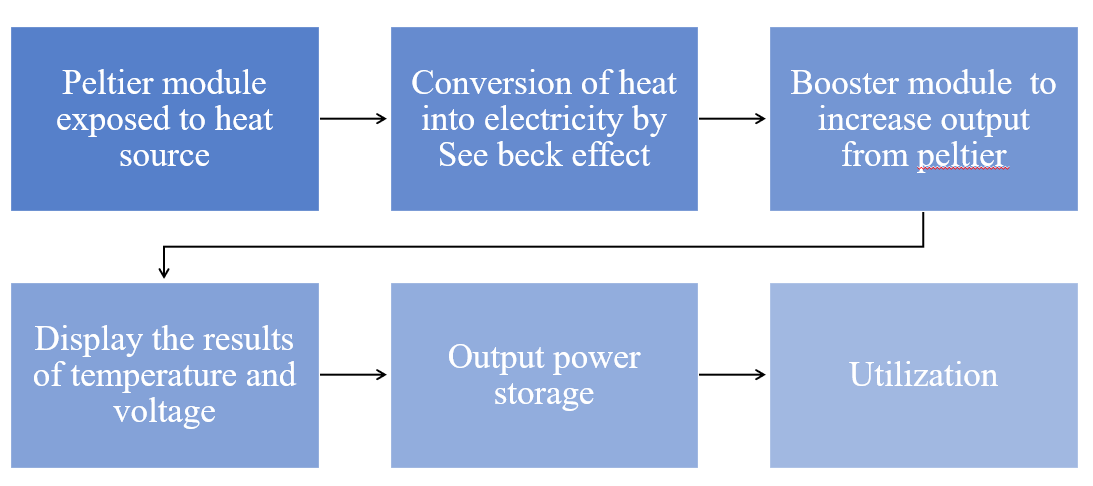

BLOCK DIAGRAM:

IMAGES:

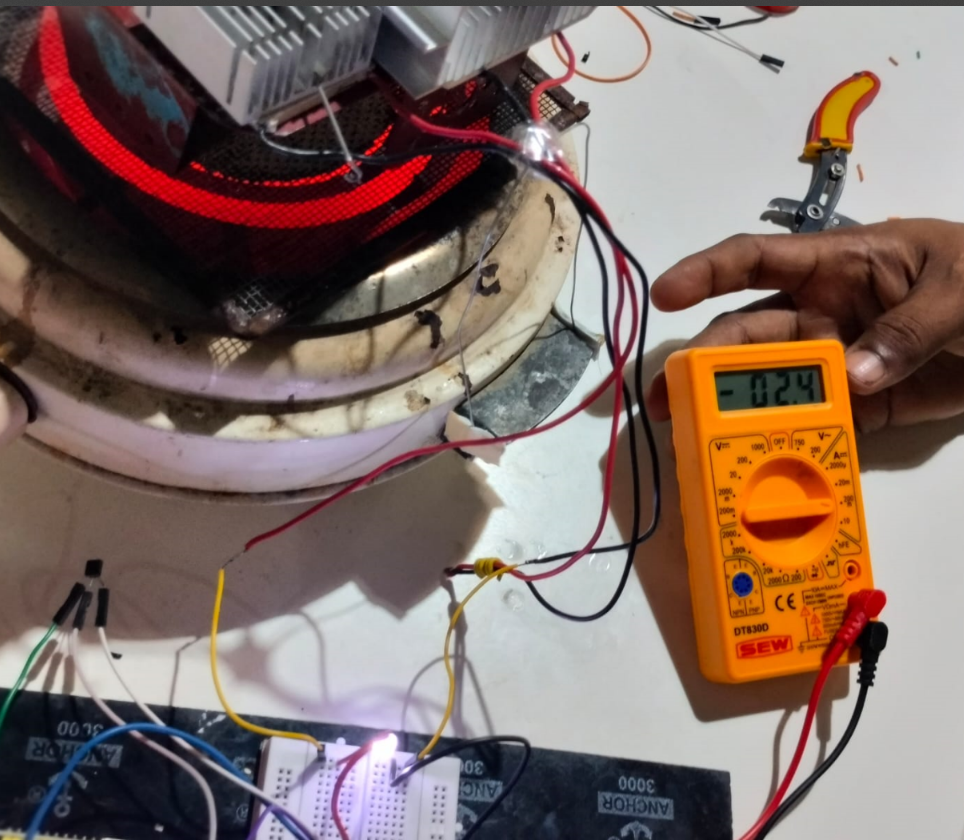

fig1.1:Testing output from booster

fiq1.2:voltage rises with temperature - LED glows(2.3v -direct output from Peltier and 12v - output from booster module (dc-dc convertor) )

Project video:

Here is a whole experiments done for the project as a video..