1.Introduction

1.1 The Importance of Gas Monitoring in Poultry Farm

Nonetheless, massive volumes of dangerous gases, such ammonia, are released during animal breathing, fecal decomposition, and padding degradation in intensive farming practices. In order to preserve the perfect temperature for the growth of chickens, farmers often close their poultry house during the winter. The lack of air circulation causes the concentration of ammonia (NH3) in the housing to remain high, and hens exposed to such high levels of ammonia over an extended period of time may become sick or possibly die. Ammonia emissions are primarily caused by livestock farming. Breeders' and the locals' health will be negatively impacted by ammonia that diffuses from the cattle into the atmosphere, as it can cause a variety of respiratory ailments. Thus, it is imperative to quickly and accurately detect the ammonia content in chicken housing in order to promptly direct ventilation and deodorization. This serves not only human and poultry health needs, but also pressing environmental protection and food safety concerns.

1.2 Sensor Performance And Application In Poultry Housing

There are two types of ammonia detection techniques for chicken housing: sensor techniques and laboratory techniques. For sub-ppm precision in detecting hazardous gas concentrations in animals, laboratory techniques typically employ mass spectrometry, photoacoustic spectroscopy, and Fourier transform infrared spectroscopy. Despite the fact that these instruments have the advantages of simultaneous multi-component measurement, high sensitivity, and both qualitative and quantitative accuracy, their huge size, high cost, and complex operation make them challenging to employ for long-term field monitoring. In order to detect ammonia in poultry housing, sensor systems frequently include semiconductor or electrochemical gas sensors. Countries and regions across the world restrict the amount of ammonia in poultry houses to safeguard the health of the workers and the production of the animals. The United Egg Producers recommend that ammonia levels in chicken houses be less than 10 ppm and not more than 24 ppm. The European Union restricts ammonia in poultry to 20 ppm, whereas the United States allows a weighted average exposure limit of 50 ppm for humans for eight hours. We fitted the second harmonic peak, which we observed using standard ammonia, using the range of variation in the ammonia concentration in poultry housing. There is a strong linear link between the harmonic peak and the low ammonia levels in chicken housing.

1.3 Impact Of Excess Of Gases In Poultry Farm

In a poultry farm, too much gas can have a number of detrimental effects on the birds as well as the farm. Ammonia (NH3), which is the main gas of concern, is created when uric acid in bird droppings breaks down. This is how too much ammonia can harm your chicken farm:

Bird Health: Ammonia irritates birds' respiratory systems, causing breathing difficulties, eye irritation, and coughing. Their immune system may be compromised as a result, leaving them more vulnerable to respiratory illnesses including aracialities and bronchitis. Elevated ammonia levels can even be lethal in extreme circumstances.

Decreased Performance: Ammonia-induced respiratory irritation makes birds less active and less likely to eat. In the end, this results in decreased egg production, slower development rates, and worse flock performance overall. Worker Health: Farm workers' eyes and respiratory systems may become irritated by ammonia.

High exposure might cause headaches, wheezing, and coughing. Environmental Impact: Air pollution is caused by surplus ammonia discharged from chicken farms. If left unmanaged, it can also affect neighboring water supplies.

2.Proposed Work

2.1 Hazourdous Gas Detection System

The purpose of this proposed system is to detect and monitor hazardous gas in poultry farms. When a small amount of gas is introduced to the MQ sensor, the system monitors the gas level and displays the message "Air Contamination Found MQ "on an LCD screen. The technology that has been designed will be beneficial to the workers because it addresses issues that have been seen recently, such as respiratory disorders and irritated eyes. It assists in improving their safety standards and helps avert a significant calamity. Every sensor that is attached to the Node MCU has the ability to sense and analyze data that is sent to the Node MCU from the plants. The Node MCU processor receives data from the sensor and forwards it to the Arduino IDE through a USB connection between the ESP32 and the processor. Because of the coding, ESP32 is already preprogrammed in C; the data is sent to the mobile application. The user receives an SMS or email alert from the mobile application. Either human control or automation can be used, depending on the user. Automation can run if the user is unable to receive the message.

2.2 IOT System

The Internet of Things (IOT) is a network of mechanical and digitally connected computing devices that may transfer data across a network without requiring human-tohuman or human-to-computer interaction. Unique identifiers (UIDs) are assigned to these devices. The concept of the Internet of things has evolved as a result of the confluence of numerous technologies, real-time analytics, machine learning, commodity sensors, embedded systems, and more. The conventional disciplines of automation, control systems, embedded systems, wireless sensor networks, and others make the Internet of things viable. Products categorized as "smart home" in the consumer market include equipment and appliances that support one or more common ecosystems and can be controlled by ecosystem-related gadgets like smart speakers & smartphones.

2.3 SENSORS

To detect the quantity of gases in the air, such as carbon monoxide, alcohol, hydrogen, propane, LPG, and methane, an electronic sensor known as the MQ2 gas sensor is utilized. The MQ2 gas sensor is also known as a chemiresistor. The resistance of the sensor material changes when it comes into touch with the gas. The DHT11 is a straightforward, incredibly cheap digital temperature and humidity sensor. It uses a capacitive humidity sensor and thermistor to measure the ambient air quality before creating a digital output on the data pin (analog input pins are not needed). Time is of the essence while capturing data, notwithstanding its ease of use. An open-source platform called ESP32 is used to construct electronics projects. Electronics projects are built using the Arduino open-source platform. The Arduino system consists of a physical programmable circuit board and a computer program called the IDE (Integrated Development Environment). Computer code is developed and uploaded to the actual board using the IDE. Its different pin count consists of six analog pins, fourteen digital pins, three ground pins, and pins for each input and output. Digital pins are capable of writing and reading only one state—that is, on or off. Analog pins are useful for finer control since they can read a wide range of values. elevated susceptibility to smoke, propane, CO, hydrogen, LPG, and alcohol. Reaction time of less than ten seconds is rapid. increased sensitivity, long-lasting, and stable. A photodiode for light detection and an op-amp for sensitivity control are features of the flame sensor module. It is used to detect fires and, when discovering one, to generate a loud signal. Here, the temperature and humidity are being measured using the DHT11 sensor. DHT11 keeps an eye on the temperature and humidity levels in the chicken house. If the temperature went beyond or below the critical points of 20ºC or 70ºF, the chicks would die. Dampness may also affect the breathing of poultry birds. Between 60% and 80% is the ideal humidity range for poultry birds. A specialized NTC for temperature measurement is combined with an 8-bit microprocessor in the sensor to provide serial data output of humidity and temperature information. Since the sensor is already calibrated, connecting it to other microcontrollers is straightforward.

Lastly, the designed system is powered by lithium batteries, a family of rechargeable batteries with a high energy density that are frequently used for portable electronics, electric vehicles, etc. A voltage regulator was used to adjust the VCC to the necessary 5 V, and a relay was used as a switch.

Fig 2.3 Sensor unit

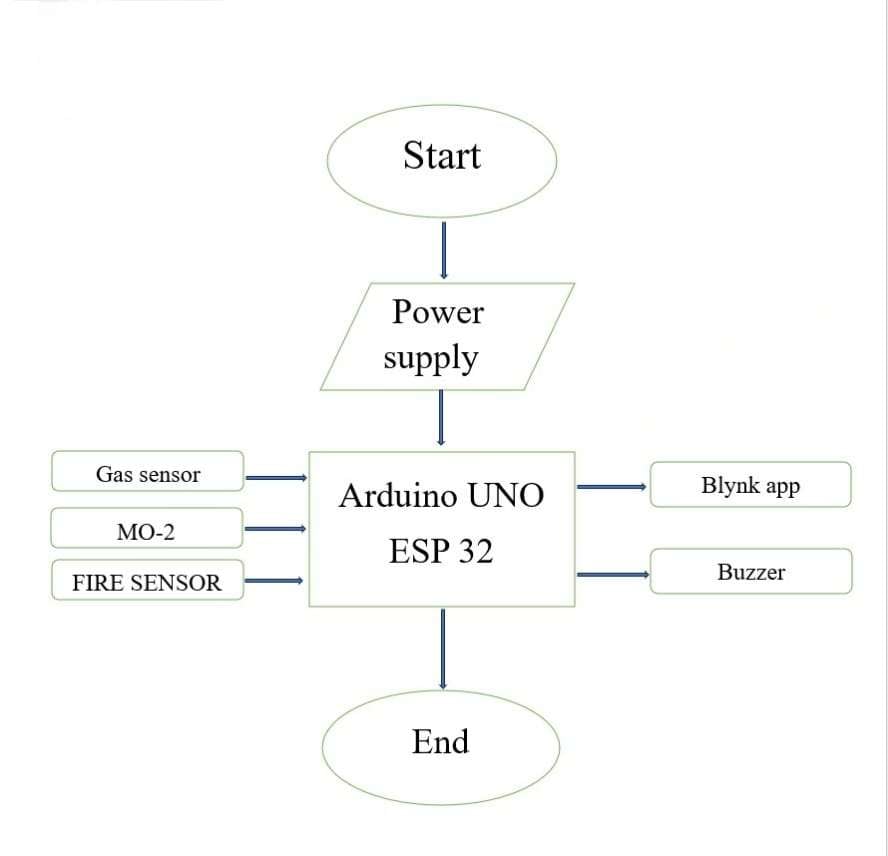

3.Flow Diagram

Fig 3.1 Work Flow

4.Results and Discussion

4.1 Test of Air Quality

Although there are other gases that have an impact on the system's air quality, butane was employed for this project's work. The poultry house was manually filled with butane gas. The MQ135 sensor detected this impurity and produced a value of 365, as seen in figure 4.1. The value produced rises as the number of impure gases in the air decreases, and falls as the concentration does.

.png)

Fig 4.1 Air Quality test

4.2 Test of Temperature

The system's capacity to measure temperature accurately and consistently was put to the test. By turning on the lamp, it was raised, which raised the air temperature within the chicken house. Figures 4.2 demonstrate how the temperature increases from 28.4°C room temperature to 30.9°C, after which the temperature was greater than needed and the lightbulb was turned off. This demonstrates the system's capacity to track and control the temperature.

.png)

Fig 4.2 Temperature test

4.3 Development Framework

The ESP32 microcontroller is physically inspected to make sure there are no evident symptoms of damage before it is powered on. If it is, we then move on to the installation process. Install the toolchain, which is a collection of applications and code compilers. Obtaining the Arduino IDE, that is, installation of software packages and source codes tailored to the ESP32. Connect modules to GPIOs and serial ports, launch an application, and manage it. The names of serial ports often contain patterns, such as "COM6" for Windows. Construct, debug, and flash the ESP32 microcontroller with the project. The project's functionality is visualized and diagnosed using the serial monitor. Create a new project on the Blynk app after setting up your login information.

Configure the motion, illumination, temperature, humidity, and air quality modules. Use the internet to link the ESP32 to Blynk.

.png)

Fig 4.3 Development Framework for ESP32 Embedded C++

Video Link