Bad condition of roads causes a lot of inconvenience to daily commuters. It is the reason behind many road accidents and the condition is getting more worse day-by-day. The present methods used for maintenance of roads require a lot of man power and also consume a lot of time. The unfinished road maintenance work affects the traffic and may lead to accidents in some cases.

Problem Statement

To reduce the manpower and time required for road maintenance work.

Solution

Introducing Pothole Patching Robot. A semi-autonomous system that can be wirelessly controlled by a single person for doing the road maintenance work, more specifically for patching potholes that need emergency maintenance more frequently to keep the traffic moving and avoid any accidents caused by bad condition of roads.

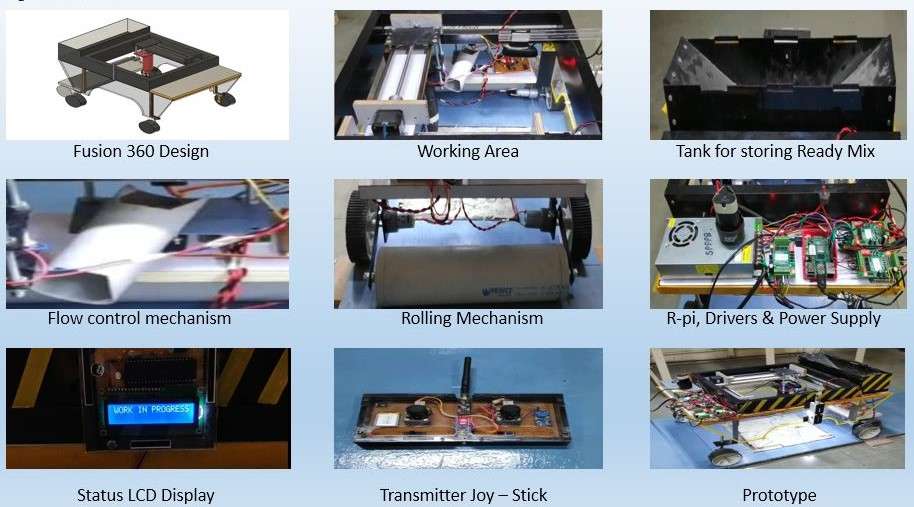

Build Process

Hardware Boards

1. Raspberry-Pi Model 4B : For Image Processing

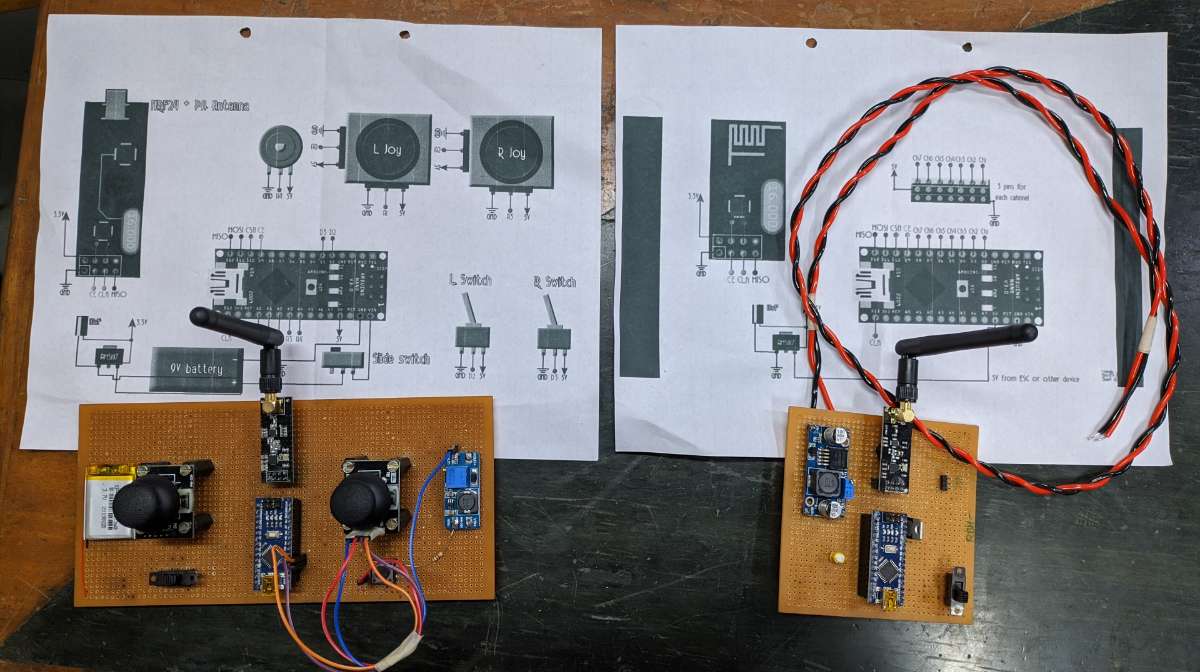

2. NRF Module : For wireless controlling of the system

3. Arduino Nano : Controlling the Transmitter and Receiver. Master-Slave configuration with NRF Module.

- Camera : To Capture Image of the Pothole

Software Tools

1. OpenCV : For Python Programming

2. Arduino IDE : For Embedded Programming

3. Fusion 360 : For 3D Modelling

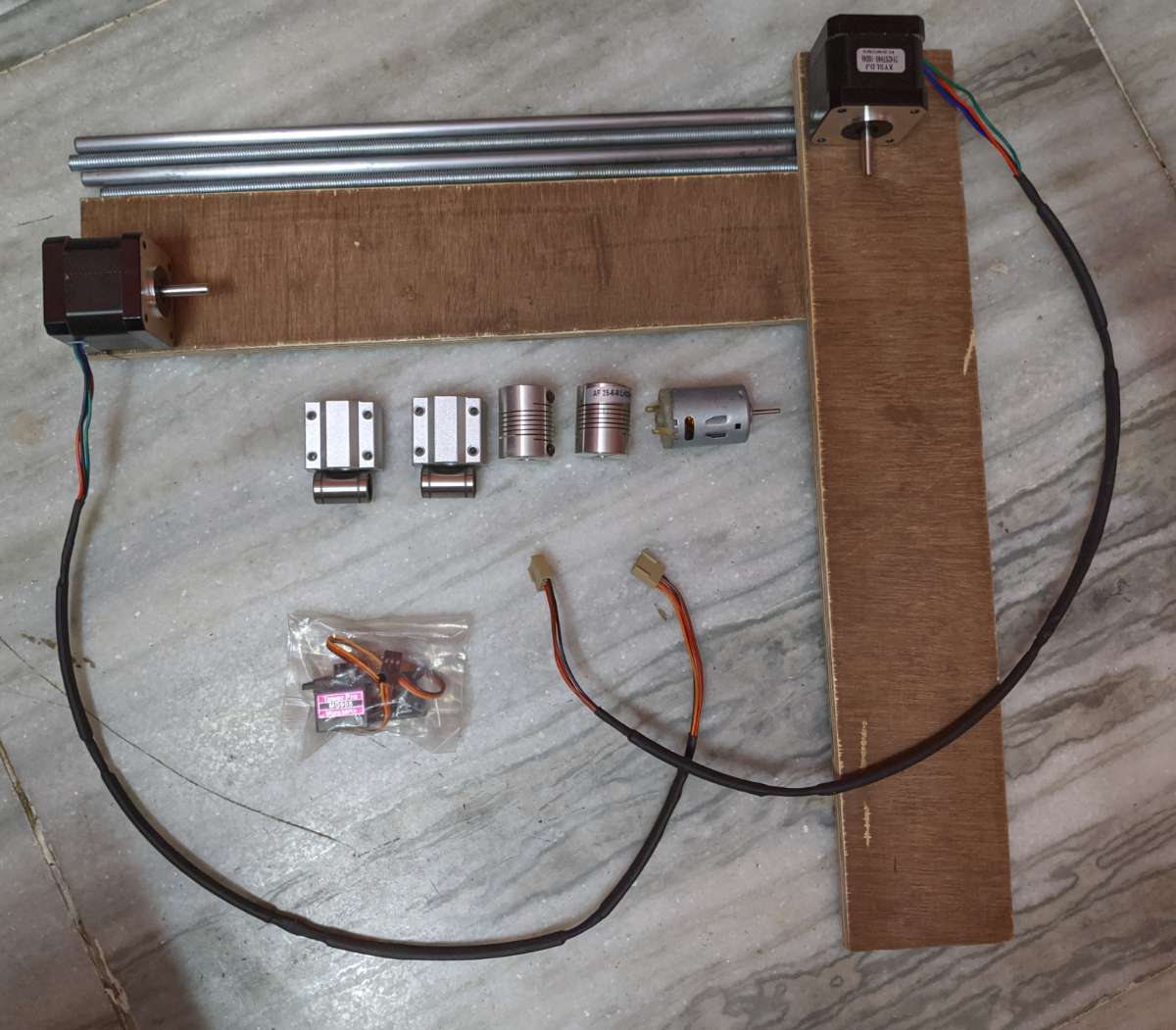

Hardware Components

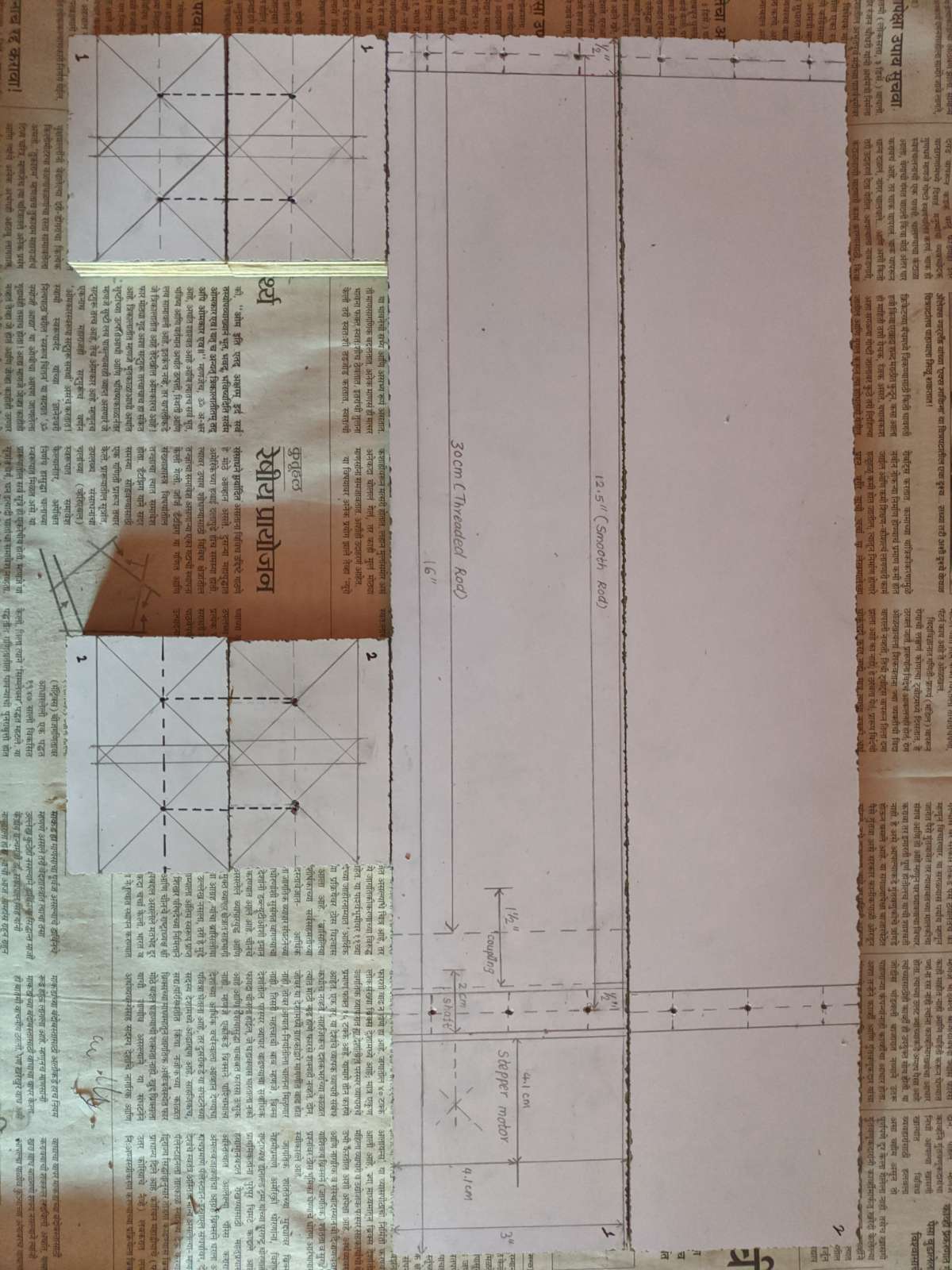

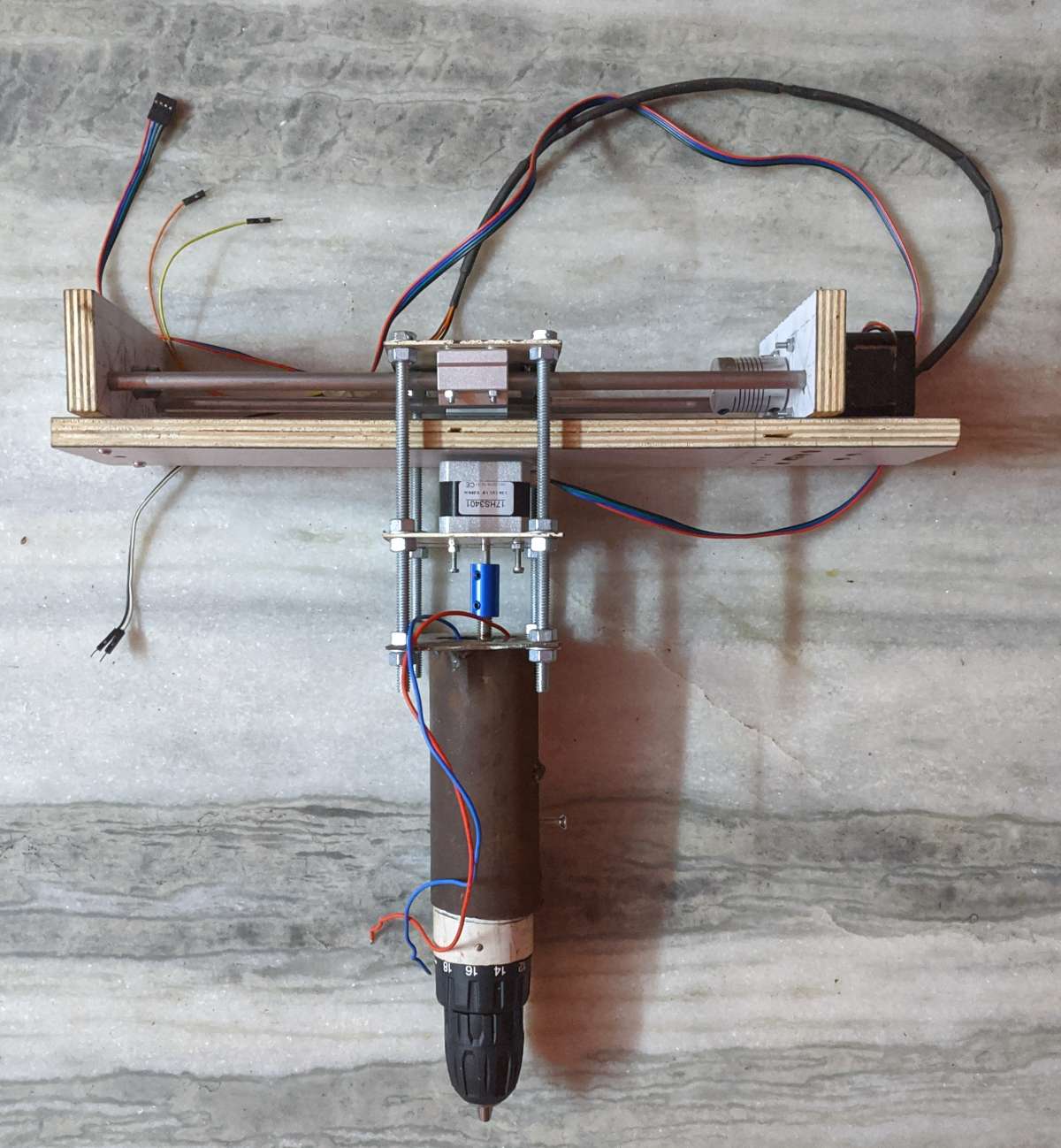

1. Nema 17 Stepper Motor : For X-Y-Z movement of the pothole cleaning mechanism

2. Geared DC Motor : For driving movement of the system

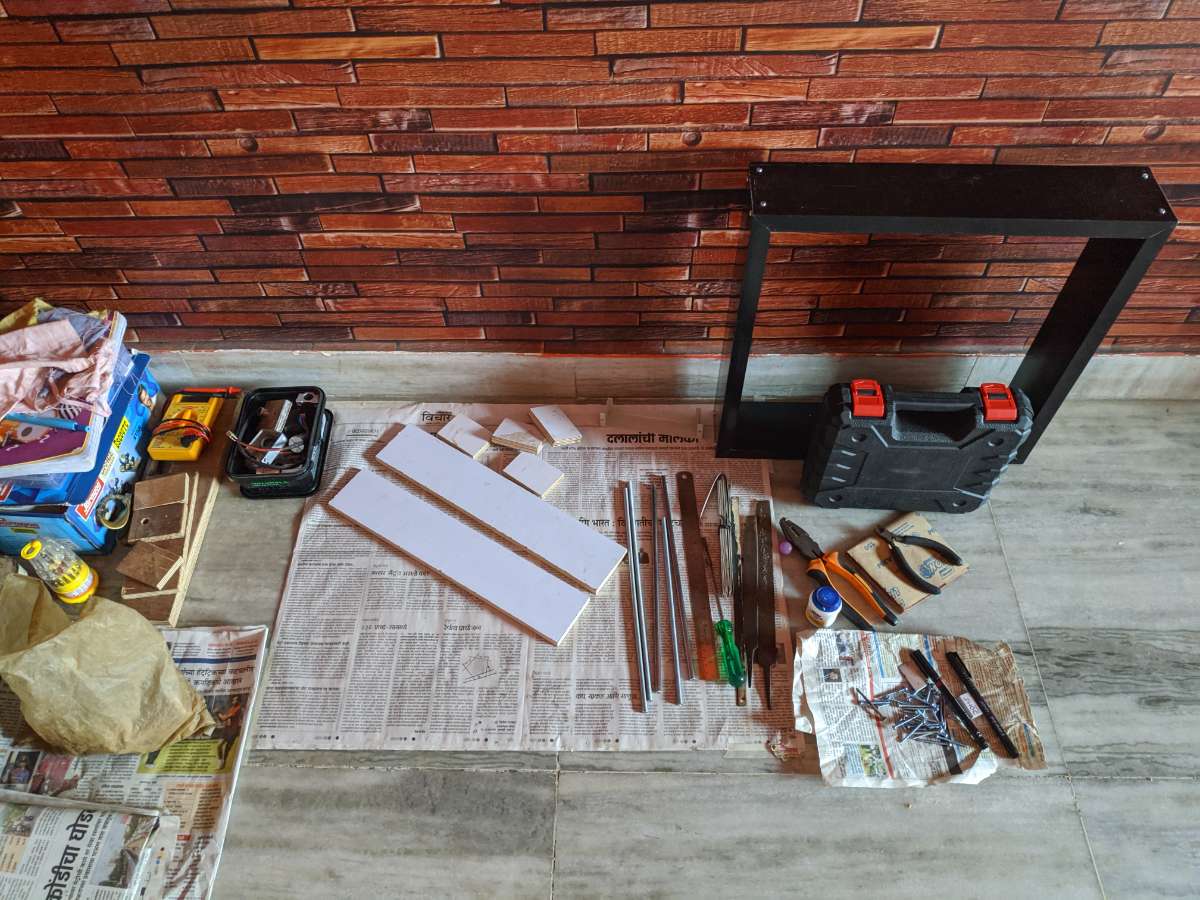

Fabrication

1. Chassis : External structure made up of metal L-angles to hold the different parts of the system together and wheels for the movement of the system.

2. Wooden Supports : For mounting the stepper motors.

3. Pothole Cleaning Mechanism : To clean the debris inside the pothole

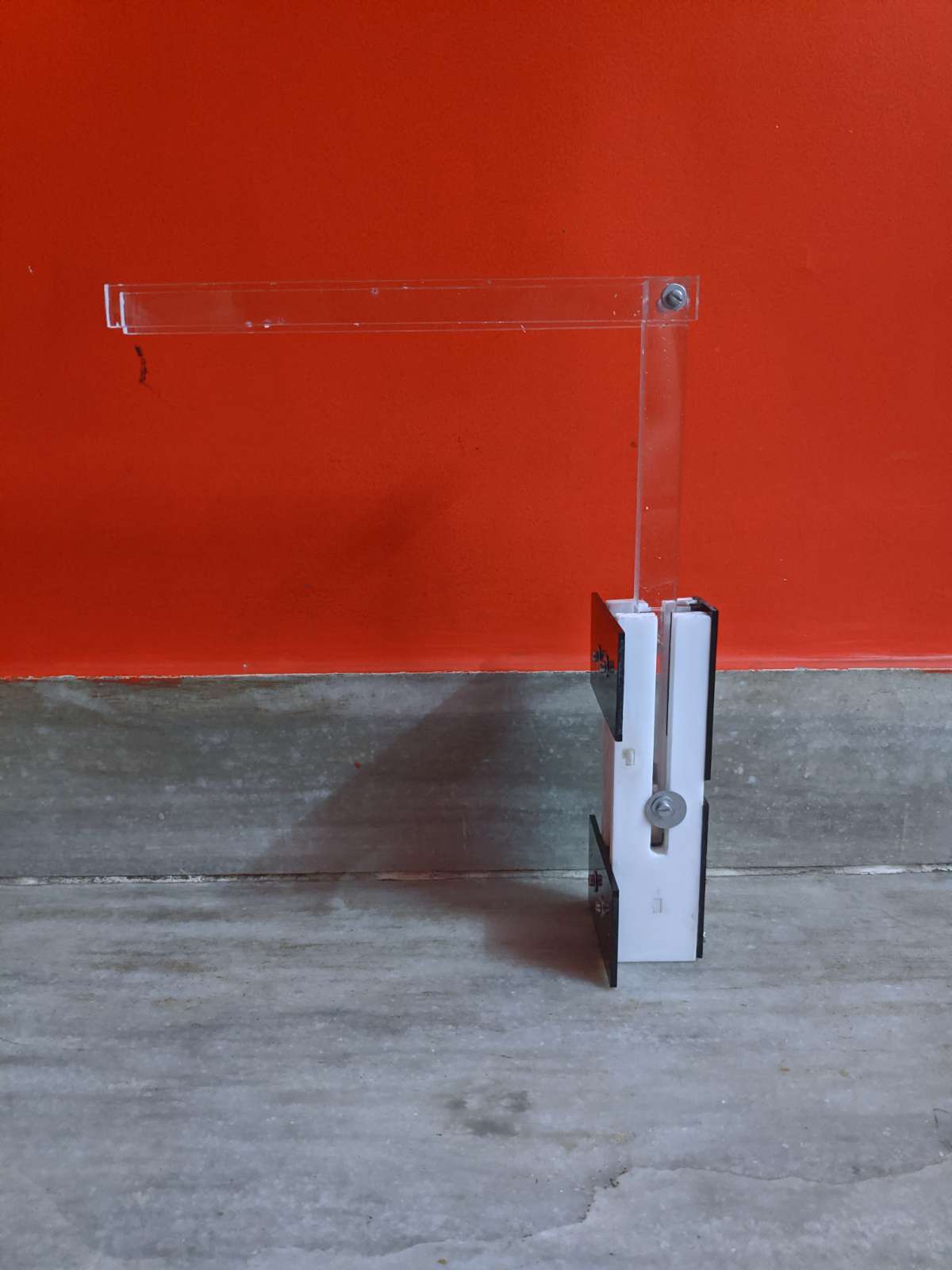

4. Camera Stand : To mount the camera with variable height

Transmitter & Receiver

- Fabricated Transmitter & Status Indicator : For displaying the status of the system

Implementation

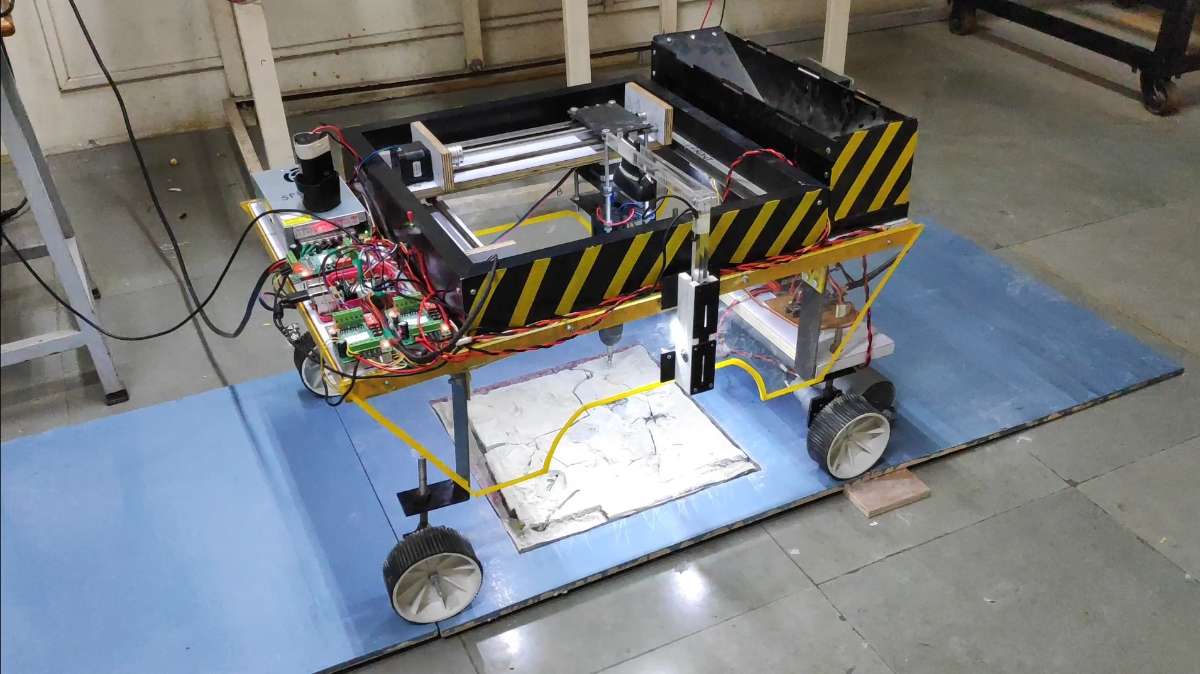

Prototype

Working

- The system operator will align the system on the road such that the pothole lies between the working area of the system.

- After aligning the system, the system will capture the image of the entire working area.

- This image will be given as a input to Raspberry-Pi.

- Using Image-Processing the size of the pothole will be determined and the exact co-ordinates and location of the pothole will be calculated.

- This co-ordinates will be used by the pothole cleaning mechanism to clean the debris inside the pothole.

- The cleaning process will be done by the system autonomously.

- After the pothole is cleaned the system operator will align the flow control mechanism over the pothole and fill the pothole with dry asphalt material which will be already stored in the system.

- After filling the pothole with dry asphalt material, the system operator will drive the system over the pothole.

- By driving the system over the pothole the pothole will get compacted by the weight of heavy roller present at the back of the system.

- Once the pothole is compacted we have temporarily patched pothole and the road can be used for commutation.

- The entire process will take around 10-15 minutes while providing us with a temporary solution for busy hours when there is heavy traffic without causing any inconvenience to the commuters.

- The pothole can then be permanently repaired when the traffic is less.

Video Demonstration

Conclusion

By developing the prototype of Pothole Patching Robot so as to be used in real life we can reduce the man power and time required for road maintenance work and can provide better and safer roads for daily commute.

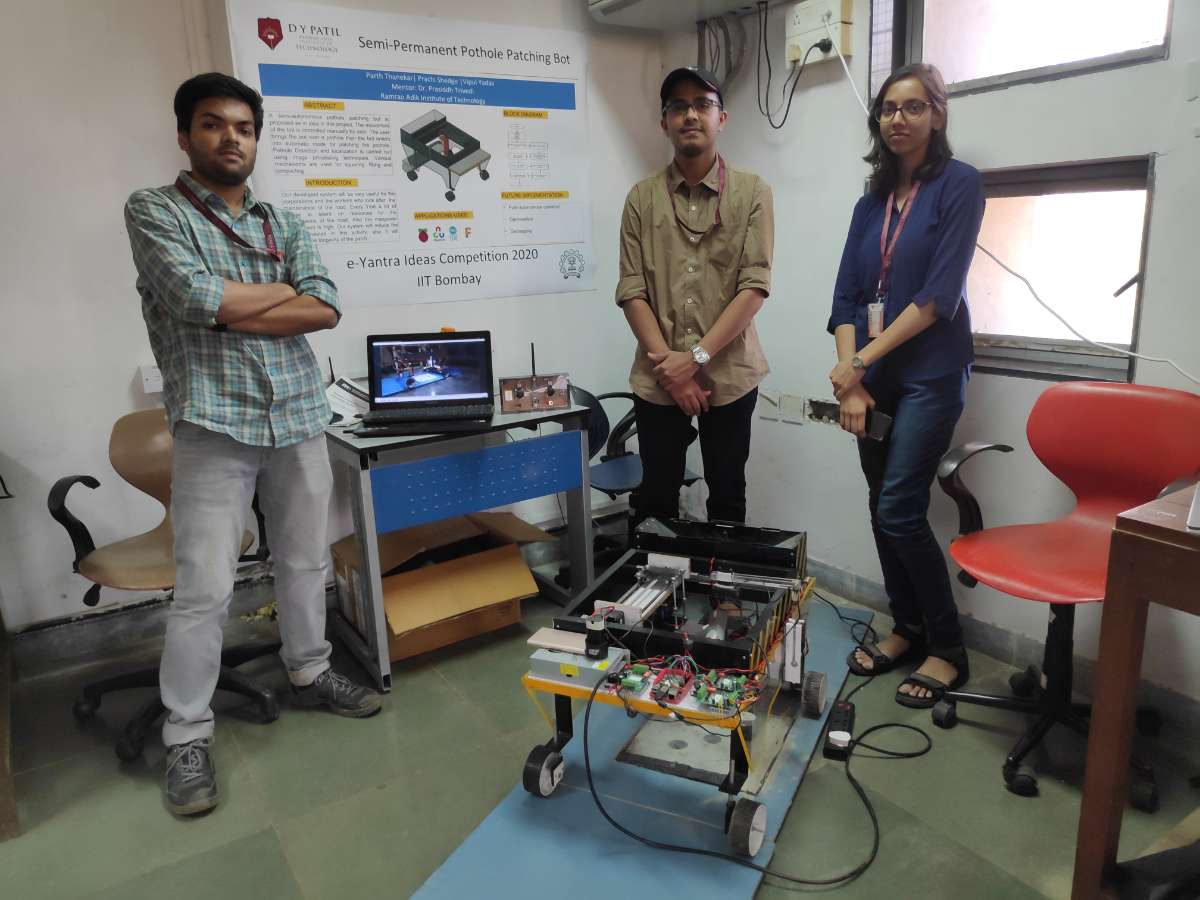

Contributors

Vipul Yadav | Parth Thanekar | Prachi Shedge | Final Year Students | Ramrao Adik Institute of Technology

Mentor :- Dr. Prasiddh Trivedi | Prof. Ramrao Adik Institue of Technology

Thank You !