Introduction :

.jpg)

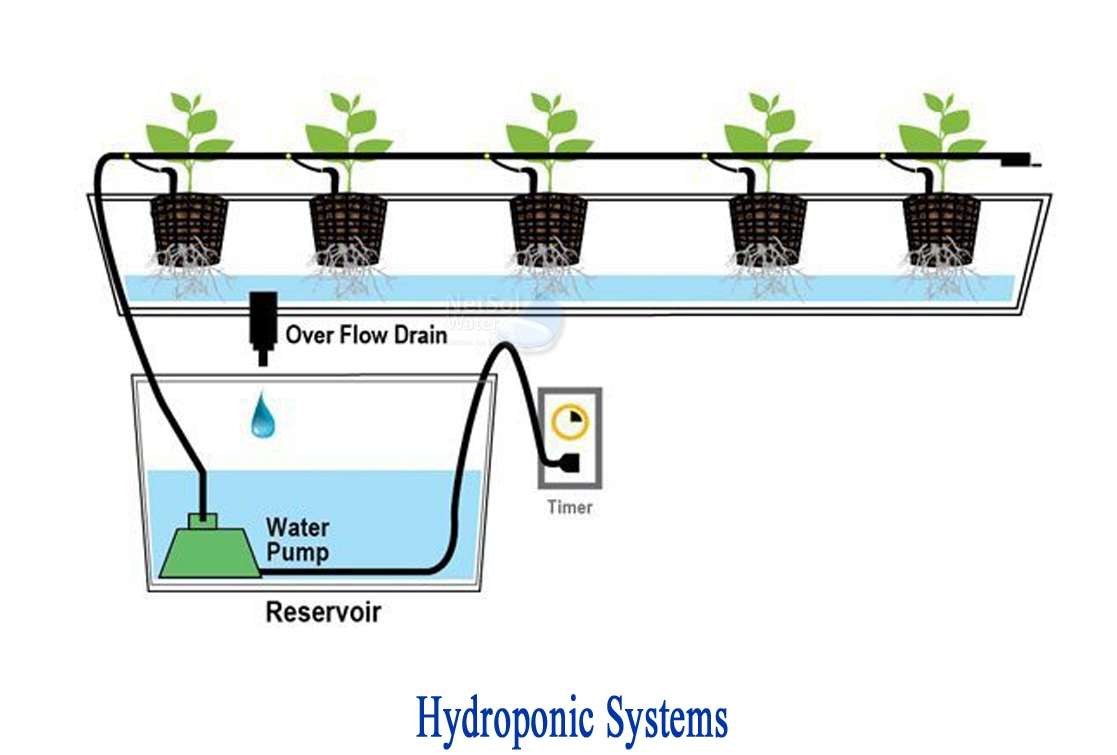

Hydroponics, a method of growing plants without soil using mineral nutrient solutions in water, has revolutionized modern agriculture. By automating a hydroponic system, we can further enhance efficiency and productivity. This article details the process of building an automated hydroponic system using an Arduino Uno board, along with various sensors and components.

Through this technique, roots absorb the nutrients present in water and fulfil their growth requirement. Furthermore, through this method, one can grow plants in liquid, sand or gravel by simply adding some nutrients to recent years, hydroponics has found application in the field of commercial production and horticulture. Similarly, residents of cities with limited space are using this method to grow fresh plants in their home and surroundings.

Working :

pH Monitoring: The pH sensor continuously measures the pH level of the nutrient solution. If the pH deviates from the desired range, the system can trigger corrective actions, such as adding pH adjusters.

Water Temperature Control: The DS18B20 sensor monitors water temperature. The system can activate heaters or coolers to maintain the optimal temperature range for the plants.

Air Temperature and Humidity Control: The temperature and humidity sensor tracks ambient conditions. A fan, controlled by the relay module, is used to regulate air temperature. If the temperature exceeds a set threshold, the fan turns on to cool the system.

Light Intensity Regulation: The LDR sensor measures light intensity. Based on the readings, the relay module controls artificial lighting to ensure the plants receive sufficient light for photosynthesis.

Water Level Monitoring: The ultrasonic sensor measures the water level in the tank. If the water level drops below a certain point, the system triggers a pump to refill the tank, ensuring plants have constant access to the nutrient solution.

Display and Monitoring: The 16x4 LCD panel provides real-time data on all monitored parameters, allowing for easy oversight and manual intervention if necessary.

Automation and Control: The 4-channel relay module automates the system by switching various components on and off based on sensor readings, ensuring optimal conditions for plant growth.

PCB layout

.jpg)