An ion thruster (also known as ion engines) is a type of propulsion system that generates thrust by accelerating ions to high speeds and expelling them out of the back of the engine. The basic principle behind an ion thruster is to use an electric field to ionize and accelerate a propellant to produce a small but continuous thrust.

Ion thrusters are used in spacecraft propulsion systems, where their high specific impulse and low fuel consumption make them ideal for long-duration missions. They have been used in space since the 1960s, and have been steadily improved over the years.

This time I will present you a very simple way to make an effective ion thruster. I got the idea from the plasma channel where several such devices are described in the previous period.

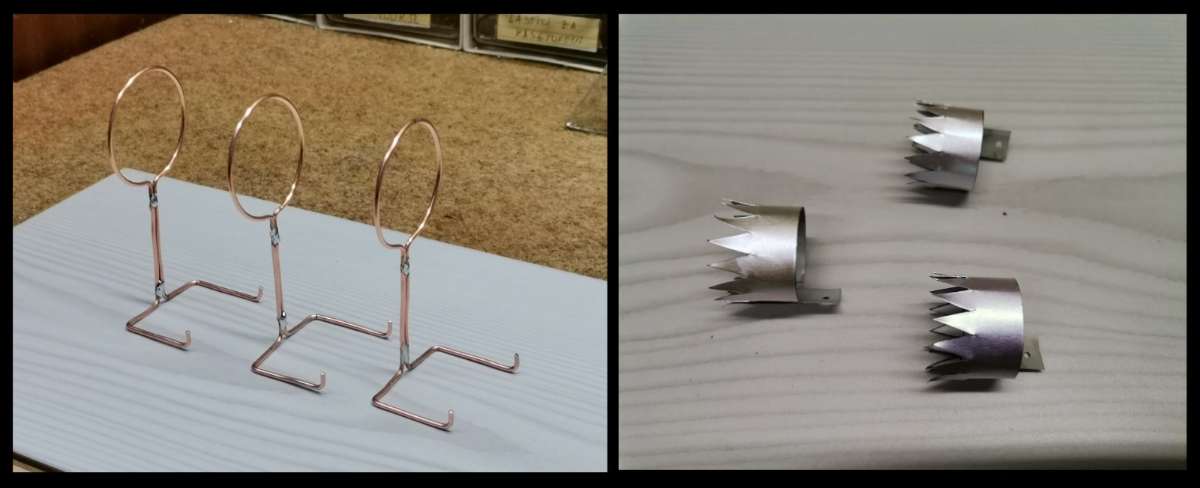

I tried to construct as simple as possible such a device that does not require precise 3D printed parts, so that it can be made by less experienced makers. From the material we need an ordinary 2.5mm copper wire used in house installations, a small metal plate (in this case aluminum), and a high voltage source.

We make one electrode from the wire and it should have approximately given shape, the dimensions are not critical, it is only important that this part has the shape of a circle. The other electrode is made from thin sheet metal as described later in the video.

If you want to make a PCB for this project, or for any other electronic project, PCBway is a great choice for you. PCBway is one of the most experienced PCB manufacturing company in China in field of PCB prototype and fabrication. They provide completed PCB assembly service with worldwide free shipping , and ISO9001 quality control system. Also, on their site there is an online gerber viewer where you can upload your gerber and drill files to render your board.

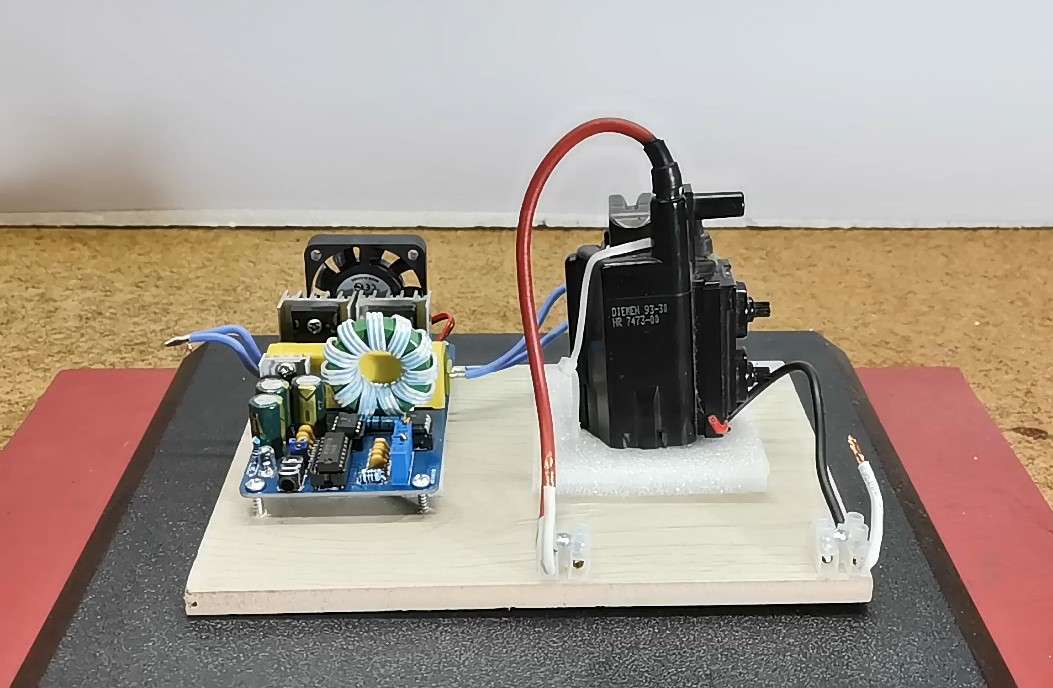

For the high voltage source I am currently using a "Plazma Speaker board" that I bought earlier for testing purposes, and for this project it turned out to be great because the output voltage can be changed simply with this trimmer potentiometer. Otherwise, any source of high voltage greater than 15-20kV can be used. You can build your own HV source described in one of my earlier videos.

Now let's first test one stage of the motor and roughly measure its characteristics. To measure the air flow I will use small anemometer, but I am not sure that the values it shows are correct, because the anemometer reacts to the electromagnetic field created by the ion thruster. For those reasons, I will also use an empirical way to measure flow using candles and thin light paper.

During the testing, I will also measure the total consumption in relation to the thrust created because this characteristic is very important in the cases where this engine is used, i.e. spaceships.

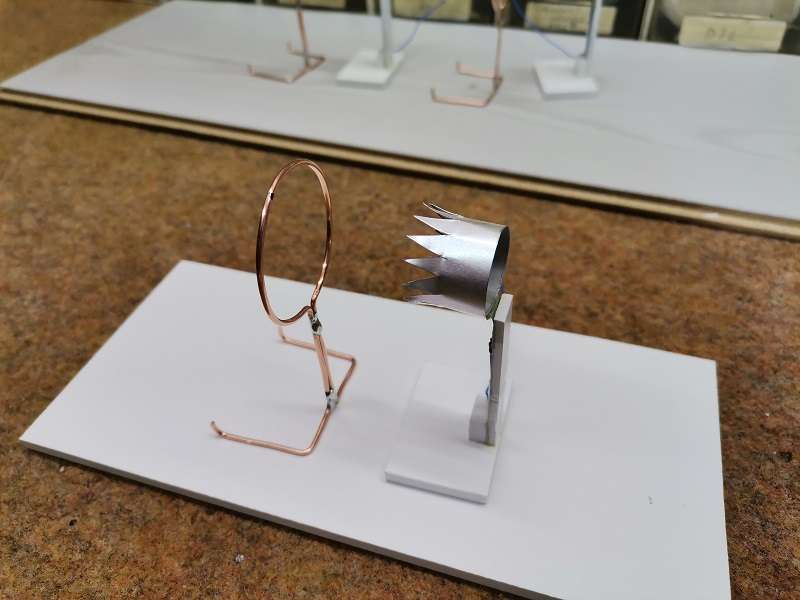

One electrode is static and glued to the base, while the other can be moved to achieve the ideal distance. To increase the thrust I will use three stages, actually three identical units placed in the same line.

The electrodes are connected by a parallel connection. Serial way of placing the motors is suitable in the case where a greater absolute thrust is needed on a small surface (for example when turning in a certain direction), while for constant movement in one direction, the stages should be placed in the same plane, one near one. As the power increases, the thrust increases proportionally. If we reduce or completely turn off the lighting, an incredibly beautiful visual effect is obtained. A trapezoid formed by plasma can be seen between the electrodes.

And finally, one note, namely after longer tests I found that the results for the strength of the thrust read on the small anemometer differ even by several times at the same thrust of the engine. As I mentioned earlier, the electromagnetic field created by the engine has a huge impact on this anemometer, so if I get a more robust anemometer in the future, I will update the data. Therefore, we will ignore these values, and the best indicator of thrust strength is the flame and thin paper methods.

In the video, you can see a detailed description of how this device is made.