.png)

Introduction

This project is based upon IoT which enables the user to drive the belt in the industry from a far location. The belt discards or enables the product to next state based upon its weight and dimension, If any of the cases rejects the product on the belt will be thrown out.

Idea Implementation

The main idea can be broken down into:

- Getting an input of how many and what products to quality check.

- Verifying the outer packaging

- Verifying the quantity.

- Separating the bad and good products.

Working

Whenever a product is flagged as bad, the controller will know what product it is, and will send a signal back to the main product line and inform them to repackage that particular product. The verification line keeps checking until it has got the exact number of products required, it verifies the number and type by cross checking with the input given.

Sensor & Technology Used

There are 4 major technologies being used in this product line:

- IR sensors: To detect and products and time the delays in the conveyor belt functioning.

- Weight/Load Sensor: This is used for the quantitative analysis (amount of milk in a tetra pack etc.)

- SONAR sensor: Used to ensure that the dimensions of the product are in order.

- IOT: This is used to compare the input given via cloud, and repeats the loop until we get the output required.

My product design hope to minimize this error by placing a number of quality and quantity checks that ensure no bad product will leave the factory.

video link-> https://drive.google.com/open?id=1Azwl9juKGl2u-__ZZEIIRmnfHZiRxkPi

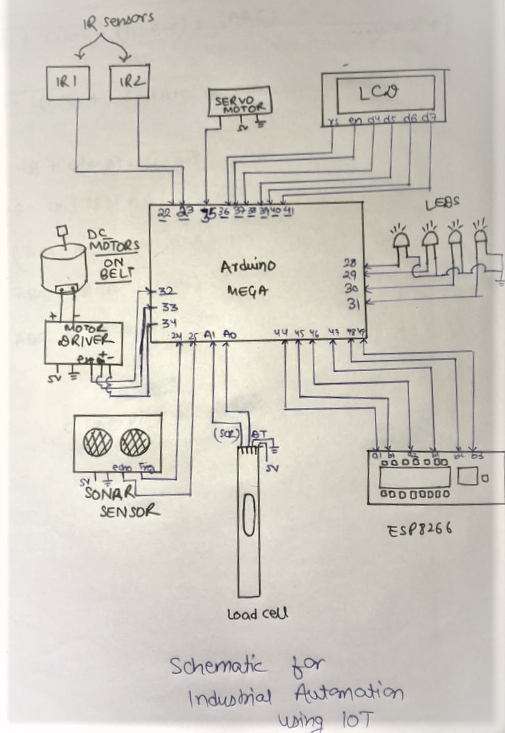

List of components: Load sensor, 2-IR sensors, colorful LEDs, LCD, Arduino MEGA, 2-dc motors, BELT, 1-sonar sensor, 1-servo motor, wires, batteries, and basic architectural components.

Circuit Diagram:

1: //Header Files

2: #include<LiquidCrystal.h>

3: #include<Q2HX711.h>

4: #include <Servo.h>

5: Servo myservo;

6:

7: int sonarread();

8: int Loadread();

9: void motoron();

10: void motoroff();

11:

12: //Ideal parameters;

13: int id_dist_a = 3;

14: int id_wt_a = 100;

15: int id_dist_b = 2.5;

16: int id_wt_b = 70;

17: int Ano,Bno;

18:

19: //LCD

20: const int rs=36,en=37,d4=38,d5=39,d6=40,d7=41;

21: LiquidCrystal lcd(rs, en, d4, d5, d6, d7);

22:

23: //IR SENSOR

24: int ir1 = 22;

25: int ir2 = 23;

26:

27: //SONAR

28: int echo = 24;

29: int trig = 25;

30:

31: //STATUS LED

32: int gLED = 28;

33: int rLED = 29;

34: int bLED = 30;

35: int stLED = 31;

36:

37: //Load Cell

38: #define SCK A1

39: #define DT A0

40: Q2HX711 cell(DT,SCK);

41: long int values = 0;

42: int load_data;

43:

44: long val = 0;

45: float count = 0;

46:

47: //DC MOTOR

48: int enb = 32;

49: int op1 = 33;

50: int op2 = 34;

51:

52: //ESP82666

53:

54: #define prod_a 42

55: #define prod_b 43

56: int a = 0;

57: int b = 0;

58: int a1 = 44;

59: int a2 = 45;

60: int a3 = 46;

61: int b1 = 47;

62: int b2 = 48;

63: int b3 = 49;SCHEMATIC:

Video demonstration:

PART1 AND PART2

APP LOOK:

.png)

Code:

//Header Files

2: #include<LiquidCrystal.h>

3: #include<Q2HX711.h>

4: #include <Servo.h>

5: Servo myservo;

6:

7: int sonarread();

8: int Loadread();

9: void motoron();

10: void motoroff();

11:

12: //Ideal parameters;

13: int id_dist_a = 3;

14: int id_wt_a = 100;

15: int id_dist_b = 2.5;

16: int id_wt_b = 70;

17: int Ano,Bno;

18:

19: //LCD

20: const int rs=36,en=37,d4=38,d5=39,d6=40,d7=41;

21: LiquidCrystal lcd(rs, en, d4, d5, d6, d7);

22:

23: //IR SENSOR

24: int ir1 = 22;

25: int ir2 = 23;

26:

27: //SONAR

28: int echo = 24;

29: int trig = 25;

30:

31: //STATUS LED

32: int gLED = 28;

33: int rLED = 29;

34: int bLED = 30;

35: int stLED = 31;

36:

37: //Load Cell

38: #define SCK A1

39: #define DT A0

40: Q2HX711 cell(DT,SCK);

41: long int values = 0;

42: int load_data;

43:

44: long val = 0;

45: float count = 0;

46:

47: //DC MOTOR

48: int enb = 32;

49: int op1 = 33;

50: int op2 = 34;

51:

52: //ESP82666

53:

54: #define prod_a 42

55: #define prod_b 43

56: int a = 0;

57: int b = 0;

58: int a1 = 44;

59: int a2 = 45;

60: int a3 = 46;

61: int b1 = 47;

62: int b2 = 48;

63: int b3 = 49;

64:

65: void setup()

66: {

67: // put your setup code here, to run once:

68:

69: //Servo

70: myservo.attach(26);

71: //IR

72: pinMode(ir1,INPUT);

73: pinMode(ir2,INPUT);

74:

75: //SONAR

76: pinMode(echo,INPUT);

77: pinMode(trig,OUTPUT);

78:

79: //STATUS LED

80: pinMode(gLED,OUTPUT);

81: pinMode(rLED,OUTPUT);

82: pinMode(bLED,OUTPUT);

83: pinMode(stLED,OUTPUT);

84:

85: //Load cell

86: pinMode(DT,INPUT);

87: pinMode(SCK,INPUT);

88:

89: //DC MOTOR

90: pinMode(enb,OUTPUT);

91: pinMode(op1,OUTPUT);

92: pinMode(op2,OUTPUT);

93:

94: //esp8266

95: pinMode(prod_a,INPUT);

96: pinMode(prod_b,INPUT);

97: pinMode(a1,INPUT);

98: pinMode(a2,INPUT);

99: pinMode(a3,INPUT);

100: pinMode(b1,INPUT);

101: pinMode(b2,INPUT);

102: pinMode(b3,INPUT);

103: //a and b are the indication of prod A and prod B

104:

105: //LCD

106: lcd.begin(16, 2);

107: lcd.println("Randiyarasan");

108:

109: Serial.begin(9600);

110: }

111:

112: void loop()

113: {

114: // put your main code here

115: while( a == 0 || b == 0)

116: {

117: lcd.clear();

118: lcd.setCursor(0,0);

119: lcd.println("Plz enter prod");

120: lcd.setCursor(0,1);

121: lcd.println("A and/or B");

122: a = digitalRead(prod_a);

123: while(a == 1)

124: {

125:

126: int A1 = digitalRead(a1);

127: int A2 = digitalRead(a2);

128: int A3 = digitalRead(a3);

129:

130: if(A1 == 1 || A2 == 1 || A3 == 1)

131: {

132: Ano = A1*0+A2*1+A3*2;

133: break;

134: }

135: }

136: b = digitalRead(prod_b);

137: while(b == 1)

138: {

139: int B4 = digitalRead(b1);

140: int B2 = digitalRead(b2);

141: int B3 = digitalRead(b3);

142:

143: if(B4 == 1 || B2 == 1 || B3 == 1)

144: {

145: Bno = B4*0+B2*1+B3*2;

146: break;

147: }

148: }

149: }

150:

151: lcd.clear();

152: lcd.setCursor(0,0);

153: lcd.println("A = %d");

154: lcd.setCursor(0,1);

155: lcd.println("B = %d");

156:

157:

158: //Starting the process

159: digitalWrite(stLED,1);

160:

161: //Process for product A

162: for(int delta = 0;delta < Ano; delta++)

163: {

164: motoroff();

165: while( digitalRead(ir1) != 1 ){

166: lcd.clear();

167: lcd.println("Place product A");

168: }

169:

170: while(digitalRead(ir2)!=0)

171: {

172: motoron();

173: }

174:

175: motoroff();

176:

177: int dist = sonarread();

178: int weight = Loadread();

179: if(weight>id_wt_a+10 || weight<id_wt_a-10 || dist>id_dist_a+1 || dist<id_dist_a-1)

180: {

181: delta = delta-1;

182: lcd.clear();

183: lcd.println("Faulty product A");

184: digitalWrite(rLED,1);

185: myservo.write(90);

186: delay(100);

187: myservo.write(0);

188: }

189: else{

190: motoron();

191: delay(2000);

192: lcd.clear();

193: lcd.println("Success");

194: }

195: }

196:

197:

198:

199: //Process for product b

200: for(int delta = 0;delta < Bno; delta++)

201: {

202: motoroff();

203: while(digitalRead(ir1) != 1)

204: {

205: lcd.clear();

206: lcd.println("Place product B");

207: }

208:

209: while(digitalRead(ir2)!=0)

210: {

211: motoron();

212: }

213:

214: motoroff();

215:

216: int dist = sonarread();

217: int weight = Loadread();

218: if(weight>id_wt_b+10 || weight<id_wt_b-10 || dist>id_dist_b+1 || dist<id_dist_b-1)

219: {

220: delta = delta-1;

221: lcd.clear();

222: lcd.println("Faulty product B");

223: digitalWrite(rLED,1);

224: myservo.write(90);

225: delay(100);

226: myservo.write(0);

227: }

228: else

229: {

230: motoron();

231: delay(2000);

232: lcd.clear();

233: lcd.println("Success");

234: }

235: }

236: }

237:

238: //distancce function

239: int sonarread()

240: {

241: digitalWrite(trig,0);

242: delayMicroseconds(2);

243:

244: digitalWrite(trig,1);

245: delayMicroseconds(10);

246: digitalWrite(trig,0);

247:

248: int duration = pulseIn(12,1);

249: int distance = duration*0.034/2;

250:

251: return distance;

252: }

253:

254: //Weight function

255: int Loadread()

256: {

257: count = count +1;

258: for(int i=0;i<15;i++)

259: {

260: val = 0.5*val+0.5*cell.read();

261: load_data = -((val-8547083)/450);

262: }

263: return load_data;

264: }

265:

266: //motor functions

267: void motoron()

268: {

269: digitalWrite(enb,1);

270: digitalWrite(op1,1);

271: digitalWrite(op2,0);

272: }

273: void motoroff()

274: {

275: digitalWrite(enb,0);

276: digitalWrite(op1,0);

277: digitalWrite(op2,0);

278: }